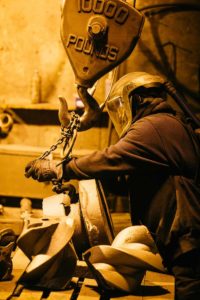

Recently, the Taylor & Fenn Company completed a large order for a longtime customer who works in the industrial food processing industry. The customer is a leading provider of industrial equipment for the production of edible products such as pasta and flour. They required fast, reliable sand casting of iron and steel components for pulverizing and milling food processing equipment.

Material Options and Maintaining Quality Standards

The customer has trusted the Taylor & Fenn Company for ferrous sand casting of their industrial components for many years. We set the industry standard for fast, high-quality sand casting with four weeks delivery for iron and five weeks delivery for steel parts. Due to their involvement in the food processing industry, the customer requested 304 and 316 stainless steel for the production of their parts. Stainless steel is an excellent choice for food processing applications, because it is easy to keep clean, has high-temperature resistance, and high resistance to physical damage.

The customer has trusted the Taylor & Fenn Company for ferrous sand casting of their industrial components for many years. We set the industry standard for fast, high-quality sand casting with four weeks delivery for iron and five weeks delivery for steel parts. Due to their involvement in the food processing industry, the customer requested 304 and 316 stainless steel for the production of their parts. Stainless steel is an excellent choice for food processing applications, because it is easy to keep clean, has high-temperature resistance, and high resistance to physical damage.

Custom Molds for Varied Food Processing Components

For this most recent order, the client required components for industrial pulverizing and milling equipment. The parts ranged in size between 1 and 800 lbs total. Thanks to our spacious shop floor, the Taylor & Fenn Company is able to produce floor molds up to 6,000 lbs. Our team worked closely with the customer’s engineers to review their existing patterns and to generate several new ones. Our team ensured each component would be completed to the client’s exact specifications. Quality parts are important in the food processing industry to help prevent excess expense for maintenance and to avoid the potential risk of food contamination from metal particulates. At the Taylor & Fenn Company, we are dedicated to providing our customers with high-quality components.

For more information about ferrous sand casting of stainless steel components for the food processing industry, contact us today.